Thanks for getting in touch.

We'll get back to you shortly.

Need an urgent response?

Need an urgent response?

Our Vacuum Glazed Traditional Box Sash Windows are specifically crafted to serve as ultra-high thermal performance sash windows for heritage projects and buildings located in conservation areas. Vacuum glazing is just 8.3mm thick, closely resembling single glazing while offering modern insulation.

This window is internally beaded for enhanced security, with applied slim glazing bars to keep the aesthetics of the original window but with a much greater performance, typically achieving a whole window U value of 1.2 – 1.1 W/m2K and acoustic ratings Rw of 29-34dB, depending on the make-up of the glass unit.

Constructed with slim frame and sash profiles, the Vacuum Glazed Traditional Box Sash Window functions with a classic system of cords, weights, and pulleys. A spring balance option is also available. These windows are typically installed within a check reveal, allowing the box to remain largely concealed behind external brick or stonework, although it can also be fitted flush with the brick face, where the box remains visible and is often finished with an architrave.

TRC’s Vacuum Glazed Traditional Box Sash can be supplied fully finished with a 3-coat spray-applied microporous water-based paint system or can be supplied primed only for a topcoat to be applied on site by others.

All our windows come with a choice of sash lifts, fasteners, locks and pulley wheels with a wide range of finish options including antique brass sash, polished chrome, satin nickel, polished brass, matt bronze and polished nickel.

Product Guidance

| Sill projection | Manufactured in Hardwood with options of Projections: 35 mm, 50mm, 60mm, 70mm, 80mm, 90mm, 100mm, 110mm. |

| Wood moisture content | 12% +/- 2% on delivery. |

| Glazing beads | Windows are internally beaded with the external rebate up stand to give the appearance of putty glazing. |

| Air Permeability | 600 Pa (Class 3) EN 12207: 2017 |

| Water Tightness | 200 Pa (Class 5A) EN 12208:2002 |

| Wind Resistance | 1600 Pa (Class 4C) EN 12210:2016 |

| Whole Window U-Value | Thermal performance is calculated by the standards of EN ISO 10077-1:2006 and achieves a U-value of 1.2-1.1 W/m²K) |

| Whole Window Acoustic rating Rw, dB | Acoustic rating is Laboratory tested to BS EN ISO 10140-2: 2010 (Airborne Sound Insulation). Window Acoustic ratings Rw 29-34 dB. |

| Anticipated Life Expectancy | 60 years with the regular maintenance |

Product Specifications

| Material | Manufactured in selected engineered laminated pine, hardwood or Accoya, sourced from sustainable and managed forestry (FSC or PFEC certified). |

| Finish | Window supplied factory finished, externally and internally with Teknos Water-based micro porous opaque to specified RAL colour, or stained finish. Aqua prime 1410, Aqua mid-2901, Aqua top 2600. |

| Glazing | Windows are internally beaded with the external rebate up stand to give the appearance of putty glazing. |

| Trickle ventilation | A controllable trickle ventilator can be fitted to the window dependant on width of frame EA 2000, 4400mm². |

| Child restrictor | Restrictors which allow the opening of the sash to be restricted to 100mm is an option. |

| Operation | A traditional box sash window uses an Iron (occasionally Lead) weight, attached to a cord, passed over a pulley and fixed to the glazed sash frame. As the window is operated the weights travel upwards or downwards concealed inside the frame. |

| Timber Species | Manufactured in selected engineered laminated pine, hardwood or Accoya, sourced from sustainable and managed forestry (FSC or PFEC certified). |

| Moisture Content | 12% +/- 2% on delivery |

| Glass | The windows to be factory fitted with 8.3-12.3mm thick sealed double-glazing unit made up of two flat tempered glass panes that are separated by micro support pillars, sealed around the edges, and formed with a vacuum chamber in the cavity. |

| Glazing Bars | Applied bars are used to achieve the slim section of traditional glazing bars. These are applied with double sided glazing tape to both faces of the sealed unit and capped with clear silicone. |

| Ironmongery | A lockable Fitch fastener and two finger pulls to the bottom sash with options in colour and finish. |

| Cill | Manufactured in Hardwood with options of Projections: 35 mm, 50mm, 60mm, 70mm, 80mm, 90mm, 100mm, 110mm. |

| Horns | Solid feature horns to top sashes are included as standard. |

| Ventilation | A controllable trickle ventilator can be fitted to the window dependant on width of frame EA 2000, 4400mm². |

| Finish as Delivered | Window supplied factory finished, externally and internally with Teknos Water-based micro porous opaque to specified RAL colour, or stained finish. Aqua prime 1410, Aqua mid-2901, Aqua top 2600. |

| Restrictors | Restrictors which allow the opening of the sash to be restricted to 100mm is an option. |

| Fixing | Installation to be carried out using best building practices and in conjunction with recommendations of TRC windows. |

| Warranty | Manufacturing and Material Defects: 10-year guarantee. Finishes: The standard three-coat opaque finished joinery guaranteed for 10 years. The stain finishes guaranteed against blistering or flaking for six years. Seals: The seals on double-glazed units are guaranteed for 10 years (from the date of delivery). Ironmongery: Functional failure is guaranteed on ironmongery for two years. |

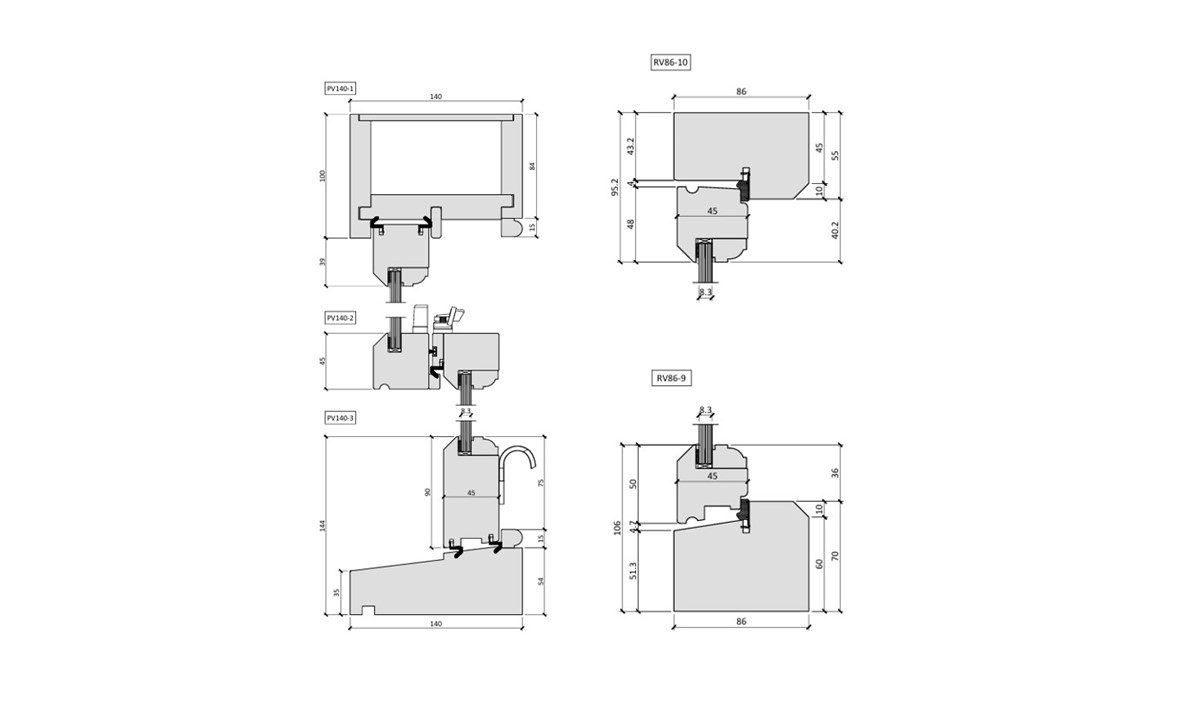

Technical Drawings

Vacuum glazing only 8.3mm thick, resembling single glazing.

Whole window U-values between 1.2 and 1.1 W/m²K.

Lifespan around 60 years with regular maintenance.

Acoustic ratings between 29 and 34 dB tested.

Fitted with 8.3-12.3mm thick sealed double-glazing unit.

Fully recyclable glazing units with no noble gases used.

Ultra-Slim Glazing with Heritage Performance

Vacuum glazed timber windows utilise two panes of glass separated by a vacuum, known as vacuum double glazing, eliminating air and significantly reducing heat transfer. This innovative approach, also known as vacuum-insulated glazing or insulated glazing, results in exceptional thermal insulation, improved sound reduction, and a slim profile that maintains the integrity of historical window designs. Our vacuum glazed timber windows, featuring this advanced type of glass, are perfect for renovations in heritage areas and high-performance buildings.

How does vacuum glazing work?

Vacuum glazing works by creating an insulating vacuum between two panes of glass, reducing heat transfer and improving energy efficiency. This process involves removing air from the gap between the panes, preventing heat loss or gain through the window and providing better thermal performance.

Our vacuum glazed timber windows are designed to meet the unique challenges of listed buildings and conservation areas. They offer the charm and authenticity of traditional timber frames combined with state-of-the-art glazing technology. This combination allows for significant improvements in energy efficiency and comfort without compromising the historical integrity of the property. In older buildings, where single glazing is often the norm, our vacuum glazed timber windows provide a modern solution while still preserving the heritage of historic buildings.

Vacuum glazed windows achieve their superior performance by eliminating air between the glass panes, minimising thermal conductivity. This technology surpasses traditional double and triple glazing in insulation properties, offering significant benefits for energy efficiency and comfort. The absence of air also reduces the ‘double image’ effect often seen in standard double glazing, making it ideal for heritage properties. With its ability to provide excellent insulation through its use of a highly efficient insulator, vacuum glazing represents a perfect balance of performance and aesthetics for historical buildings with great insulation properties.

Compared to standard double glazing and triple glazing, vacuum glazing has a number of benefits, including more energy efficiency and less heat loss, better insulation, higher noise reduction, better light transmission, a slimmer profile, and a longer service life.

Vacuum glazing offers a perfect solution for architects seeking both beauty and performance. Its ultra-thin profile seamlessly integrates with heritage projects, preserving architectural integrity. Vacuum glazing prioritises comfort with exceptional thermal performance and superior insulation properties (centre-pane U-values of 0.4W/m²K) and superior G-values, keeping properties warm and bright. Vacuum glazing also prioritises safety with two panes of 4mm toughened glass and boasts sustainability as the units are fully recyclable and eliminate energy-intensive noble gases.

Need an urgent response?